All issues

Author:Hsiang-En Tseng, Ya-Lin Lee*, Yu-Hsien Lee, Ko-Chun Lin, and Wen-Jui Su

Abstract:

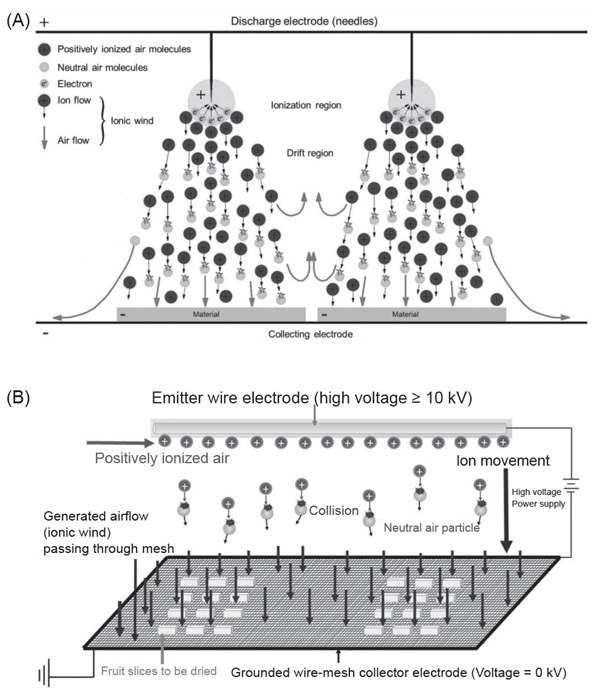

This study investigated the application of electrohydrodynamic (EHD) drying technology, utilizing a self-developed intelligent EHD dryer for drying the seeds of Camellia brevistyla, a native species of Taiwan, to compare its performance with the traditional sun drying method. The effects of the EHD dryer on drying efficiency of the seeds, and the resulting cold-pressed oil quality, including acid value (AV) and peroxide value (POV), and oil oxidative stability index (OSI) as well, were evaluated. Two batches of camellia seeds were conducted, and the EHD drying was executed at 42℃ to reach the average high temperature during the sun-drying period. Results showed that the intelligent EHD method significantly enhanced drying efficiency, resulting in a shorter drying time (48 h) compared to the sun drying method (9 d). The intelligent EHD dryer exhibited uniform drying and minimized the need for manual seed turning. Oil quality analyses revealed that the intelligent EHD drying exhibited significantly lower AV and POV values compared to the oil obtained via traditional sun drying, indicating superior oil quality. The OSI and sensory evaluation of flavor characteristics were similar for both methods. In summary, applying the intelligent EHD dryer to dry camellia seeds improves drying efficiency and enhances the quality of the pressed oil, thereby demonstrating high potential for further utilization.

Key words:Camellia brevistyla, Camellia seeds, Seeds drying method, Electrohydrodynamic drying, Oil quality

Download:![]() PDF Links

PDF Links

- 1. Bacteria in Insect Pest Management in Agriculture: The Past, Present, and Future

- 2. Multiple Applications of Yellow Mealworm (Tenebrio molitor L.) Reared on Plant-Based Substrates: Circular Agriculture, Farmed Animal Feed, and Other High-Value Products

- 3. Mini-Review on Microbial Pesticide Research for Crop Protection Assisted by Generative AI

Submit your manuscript

Submit your manuscript

Guide for authors

Guide for authors