All issues

Author:Li-Duhng Huamg, Tyng-Horng Chou, Lien-Sheng Liang and Chih-Kai Yang

Abstract:

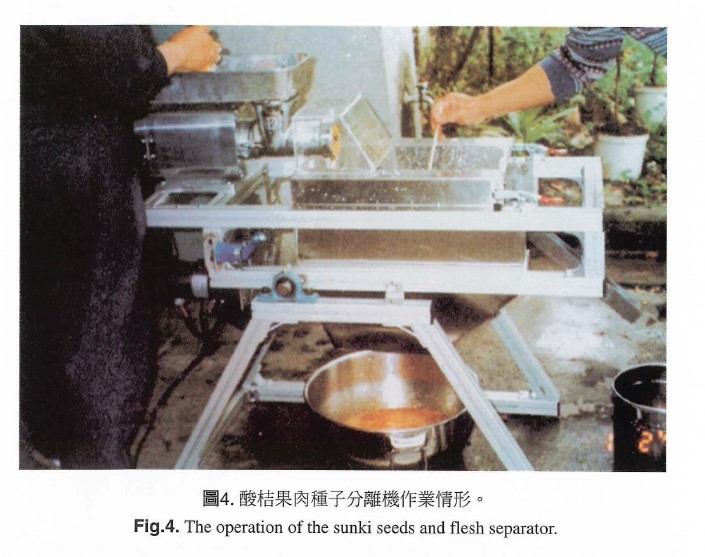

The objective of this research is to develop a machine to separate the sunki seeds from the flesh for sunki sauce production. The Hakka people on Taiwan like to use sunki sauce with cooked pork for flavor and taste. One of the production procedures is to remove the seeds from the flesh, which is very time consuming. To separate seeds from 1 kg sunki fruits takes a regular worker 12 minutes. In order to overcome this bottleneck procedure in the sunki sauce production, a separation machine was developed. The dimension of the machine is 1010 mm in length, 900 mm in height and 510 mm in width. It is composed of two parts. The crushing device squeezes the seeds from the sunki segments. The separating device separates the seeds from the flesh. The squeezing plate of a meat grinder is modified to crush sunki fruits. In order to minimize the risk of breaking the seeds during squeezing operation, the corners of the inlet holes in plate were ground to become round shaped. The stainless steel rollers are 450 mm in length and 100 mm in diameter. One of the rollers has a spiral on it for pushing the separated seeds forward to the collection chute. The machine is capable of treating 100 kg Sunki fruits per hour. It is about 20 times faster as compared to a regular human labor.

Key words:sunki, roller, separator

Download:![]() PDF Links

PDF Links

- 1. Using Digital Soil Mapping to Predict Soil Organic Carbon Stocks in Zhuoshui River Basin

- 2. Taxonomic Review of the Genus Asiophrida Medvedev, 1999 in Taiwan (Insecta: Coleoptera: Chrysomelidae: Galerucinae: Alticini), with Notes on Biology

- 3. Development of a Technique for Forecasting (or Pre-Detection) Anthracnose Disease Incidences of Green Mature Bagging Mango Fruits

Submit your manuscript

Submit your manuscript

Guide for authors

Guide for authors